Like a lot of other contracting acronyms around federal contracting and the government, NSNs can sometimes be confusing but are important for anyone who’s looking for contracting opportunities to understand. In this piece, we’ll break down what their purpose is, how to read the code’s format, why they were created, and much more.

What is an NSN?

Starting with the basics, what does NSN stand for? NSN stands for National Stock Number. These are 13-digit numerical codes that act as a part number for the Department of Defense to use for items that they purchase.

For example, if the Navy goes through a lot of a specific type of pens that they like, it can be given an NSN to make buying them on a recurring basis much easier. While this example was a full product sold commercially, NSNs are also commonly used for components like gears, pins, barrels, and other parts that might be frequently replaced over time.

History of NSNs

NSNs were actually a replacement system rather than a new idea, and they took over for the old Federal Stock Numbers in 1974. FSNs were an 11-digit code that was developed by the DoD in 1949 to identify items specified in the Army-Navy Catalog System. The switch to NSNs primarily added the 2-digit NCB code that identifies the country of origin so this can be standardized internationally. Because of this change, NSNs have now been adopted by the members of NATO, as well as some non-members.

National stock number format

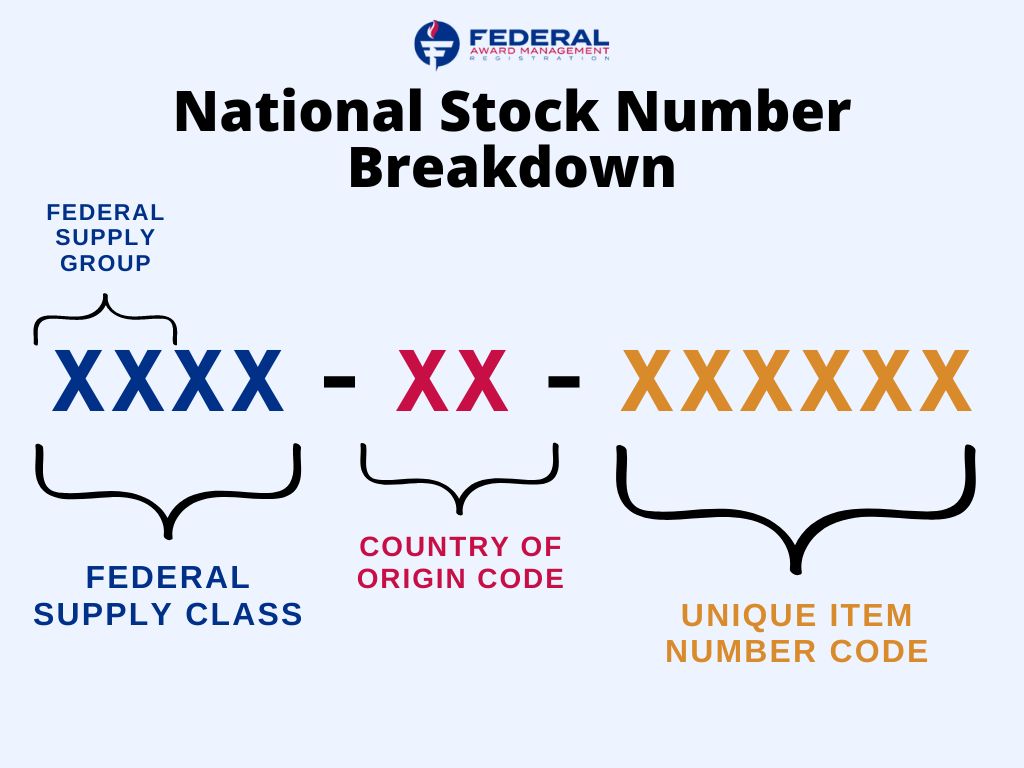

NSNs are structured relatively similarly to the NAICS codes that you needed to look up and determine what industry your company works in. Like NAICS codes, NSNs are broken down into portions of the code that refer to different information that gets more specific as you move towards the end of the NSN. These parts are:

- First 2 digits – Federal Supply Group specifies the broad category the product falls into.

- First 4 digits – Together these specify the Federal Supply Class and the general family of items that the product falls into.

- Next 2 digits – This middle section is the National Codification Bureau code and indicates the country of origin, or the country that requested this NSN to be created for the item (00 and 01 are the NCB codes for the United States).

- Last 7 digits – The final portion of any NSN is the 7-digit item number that is unique to the product it was created for.

These four major components of an NSN explain what category the item is in, which country requested the code, and the unique identifier of this particular item.

NSNs vs. NIINs

On the note of breaking down NSNs’ structure, they can also be broken down into two primary sections (rather than three). This combines the 2-digit NCB code with the 7-digit item number to create the NIIN (National Item Identification Number). Therefore, the 4-digit FSCG code and 9-digit NIIN come together to form the full NSN code.

What are National Stock Numbers used for?

Now that we understand how NSN codes work and what they specify, what does that have to do with federal contracting? Because this is a common standardized system used by the DoD, you might run into its use if you’re competing for military contracts. Additionally, this is important information for all federal contracting participants because the system provides another way to specify items that you might be dealing with, and will be the same no matter where you are or who you’re talking to.

How to look up National Stock Number data

If you need to look up an NSN (either the NSN of an item or what item an NSN is referring to), there are a number of ways to find the information. While you can download spreadsheets and data directly from the DLA (Defence Logistics Agency), it’s much easier to use a search engine like ISO Group’s here. This makes it easy to search for a code, keyword, or just browse by category.

What happens if you need to update an NSN?

National Stock Numbers (NSNs) are crucial for efficient government contracting, but they aren’t forever. Accurate and timely NSN updates are important for maintaining smooth supply chain operations and avoiding potential contract issues. With that being said, here are the most common scenarios that might necessitate an NSN update:

- Product modifications: When a product undergoes significant changes, such as improved performance or added features, a new NSN might be required to accurately reflect the new specifications.

- Specification changes: If the technical requirements or standards for a product change, the associated NSN may need to be adjusted to align with the new specifications.

- Corrections or errors: Mistakes can happen, and if an NSN contains incorrect information, it’s essential to initiate an update to rectify the issue.

- Packaging changes: Alterations to product packaging, such as size or material, can sometimes necessitate an NSN update.

See how we can boost your contracting business!

If you’re ready to boost your viability in the federal contracting space, FAMR can be a reliable partner in your corner to optimize your chances of winning contracts. Not only that, but we can help you get certifications that might have millions of dollars in contracts that only certified businesses can compete for. Get in touch with us today!